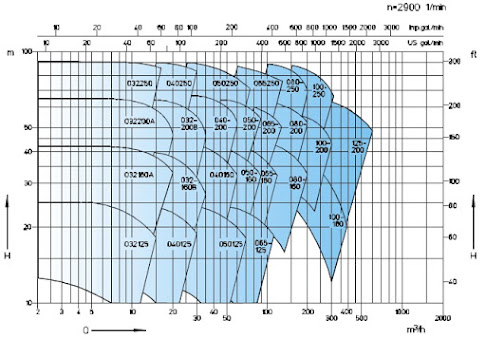

Có nhiều kích cỡ vỏ bơm (casing) bao gồm 031125 031160 031200 031250 040160 040200 040250 040315 050160 050200 050250 050315 065160 065200 065250 065315 080160 080200 080250 080315 100160 100200 100250 100315 125200 125250 150200 150250 150315 150400 150500 200250 200315 200400 200500

Đặc tính kỹ thuật bao gồm:

Lưu lượng: Tối đa 1000 m3/h

Cột áp: Tối đa 95 m

Tốc độ: Tối đa 3600 vòng/phút

Nhiệt độ: Tối đa 350 độ C

Áp suất vỏ bơm: PN 16

Shaft sealing: Sử dụng mechanical seal hay radial seal ring

Kết nối mặt bích: DIN EN 1092-2 PN 16 / 25

Chiều quay của bơm: Theo chiều kim đồng hồ khi nhìn từ hướng motor

APPLICATION

Volute pumps of the series ZTN have been specially developed for

handling of mineral and synthetic heat transfer oils. The pumps

may be used in installations with positive or negative suction

pressure.

Especially to be emphasised is the application in plants of:

The chemical industry:heating of agitators, reactors, drying plants, polymerisationplants, plants for conveying high-viscous products andproducing plastic materials and synthetic fibres.The rubber and plastic industry:heating of calendars, melting pots, power presses forplastics, automatic injection moulding machines, productionof PVC adhesive tape.The food industry:heating of baking and fish-frying ovens, distillation of fattyacids and glycerine, fat softening plants, production ofpotato chips and milk powder.The paper industry and laundries:calendar rolls, production of corrugated cardboard, heatingof washing machines, mangles and dryers.

DESIGN

Horizontal, single-stage volute pumps with the dimensions and

nominal ratings to 24255/EN 733 in back pull out design* which

permits the removal of the complete bearing unit toward the drive

end without removing the pump casing from the pipe work. If a

spacer coupling is installed it is also unnecessary to disconnect

the motor.

The programme comprises 38 pump sizes, but only three shaft

assemblies are required owing to the unit construction system.

Within each shaft assembly, shafts, shaft sealing, impeller

fastenings, bearing bracket and bearing covers are interchangeable.

The DIN 4754 regulations are complied with.

Should heat carrier seepage occur from the shaft seal, it is

ensured that the leakage will be drained off and collected

completely.

1) from size 150315 to 200500

* due to additional sizes the performance range is increased to

higher output rates.

CONSTRUCTION

Casing pressure:

Maximal 16 bar from 0 °C to 120 °C

Maximal 13 bar from 120 °C to 300 °C

Maximal 10 bar from 300 °C to 350 °C

Intermediate values can be obtained by interpolation.

Please note:

Technical rules and safety regulations.

Max. Casing pressure = inlet pressure + zero head

Admissible inlet pressure (system pressure) = 5 bar when

using shaft sealing 002.

Admissible inlet pressure = admissible casing pressure when

using shaft sealing GBC.

Flanges location:

Axial suction flange, discharge flange radially upwards.

Flanges:

The flanges comply with DIN EN1092-2/PN 16, resp. PN 25.

Flanges drilled to according to ANSI (previous ASA) 150 can

be supplied.

Hydraulic:

Designation of this construction type: A, B, D

Bearing:

One grease-lubricated grooved ball bearing resp. 2 inclined

ball bearings (the first grease filling is made in the factory) and

one internal liquid flushed sleeve bearing.

Designation of this construction type: .A

Direction of rotation:

Clockwise, when looking at the pump from the drive end.

Shaft sealing:

Code 002: several radial shaft seal rings arranged in

in series; uncooled

Code GBC: unbalanced bellows mechanical seal

seal face materials cast chromium steel/carbon

elastomer FPM (Viton)

General remarks:

For horizontal volute pumps CLOSE COUPLED construction with STANDARD motor for nominal performances and flange connections as per

EN 733 refer to our series ZTK.

For INLINE pumps with the same drive unit, consisting of bearing bracket with bearing, stub shaft and mechanical seal, casing cover, impeller

and impeller nut, refer to our series ZTI.

For equipping hot media systems a complete programme is available for a flow range between 1-600 m3/h consisting of the range:

ZEN volute pumps to EN 22858, tmax 230 °C PN 40. Hot water design.ZDN volute pumps to EN 22858, tmax 207 °C PN 25. Hot water design.ZHN volute pumps to EN 733, tmax 180 °C PN 16. Hot water design.ZLI volute pumps to EN 733 as INLINE construction, tmax 150 °C PN 25. Hot water design.

Technical documentation on these programmes will readily be supplied on request.

Performance graph

Link download catalogue để tham khảo thêm: Catalogue bơm ly tâm ZTND